2 min read

Preparations for Next Moonwalk Simulations Underway (and Underwater)  The thermal protection system on the outside of the space shuttle included hundreds of ceramic tiles custom made for the orbiter. These reflected heat off the shuttle’s outside surface during atmospheric re-entry and were an inspiration for the ceramic ingredients in Super Therm. Credit: NASA Without proper insulation, sunlight can make buildings feel like ovens. In the late 1980s, Joseph Pritchett aimed to solve this problem by developing a coating for building insulation. He knew of NASA’s experience with thermal testing, particularly with ceramics, which have several uses for the agency. Their heat-resistant properties make them excellent materials for spacecraft reentry shields, and their durability is perfect for airplane components. Pritchett thought by infusing paints with both insulating ceramic compounds and tough, resilient polymers, he could develop an insulation coating with the best features of both.

The thermal protection system on the outside of the space shuttle included hundreds of ceramic tiles custom made for the orbiter. These reflected heat off the shuttle’s outside surface during atmospheric re-entry and were an inspiration for the ceramic ingredients in Super Therm. Credit: NASA Without proper insulation, sunlight can make buildings feel like ovens. In the late 1980s, Joseph Pritchett aimed to solve this problem by developing a coating for building insulation. He knew of NASA’s experience with thermal testing, particularly with ceramics, which have several uses for the agency. Their heat-resistant properties make them excellent materials for spacecraft reentry shields, and their durability is perfect for airplane components. Pritchett thought by infusing paints with both insulating ceramic compounds and tough, resilient polymers, he could develop an insulation coating with the best features of both.

Pritchett contacted the materials lab at NASA’s Marshall Space Flight Center in Huntsville, Alabama, through the center’s Technology Transfer Office. The facility had many ways to test heat-resistant materials, and the Marshall engineers and research scientists provided Pritchett with lists of material compounds to test for his insulation coating.

Super Therm has been applied in several places, including handrails on the Hoover Dam Bypass Bridge over the Colorado River. The selection of its makeup of ceramic and polymeric materials was assisted by NASA scientists.Credit: Superior Products InternationaI II, LLC Over a period of six years, Pritchett tested every compound on the lists NASA provided, narrowing down the potential compounds until he found the ideal insulation. Pritchett founded Superior Products International II, Inc. of Shawnee, Kansas, in 1995. His product, dubbed Super Therm, is a composite of both ceramic and polymeric materials. In 2011, when tested by Oak Ridge National Laboratory in Tennessee, Pritchett’s product proved successful in saving energy when cooling homes.

Super Therm has been applied in several places, including handrails on the Hoover Dam Bypass Bridge over the Colorado River. The selection of its makeup of ceramic and polymeric materials was assisted by NASA scientists.Credit: Superior Products InternationaI II, LLC Over a period of six years, Pritchett tested every compound on the lists NASA provided, narrowing down the potential compounds until he found the ideal insulation. Pritchett founded Superior Products International II, Inc. of Shawnee, Kansas, in 1995. His product, dubbed Super Therm, is a composite of both ceramic and polymeric materials. In 2011, when tested by Oak Ridge National Laboratory in Tennessee, Pritchett’s product proved successful in saving energy when cooling homes.

The engineers at Marshall played a pivotal role in Super Therm’s development, as their knowledge was key to finding the right ceramic material. In addition to insulation for buildings, the material has been used in other industrial applications, such as keeping equipment like tanks and pumps cool on oil rigs. Pritchett’s Super Therm is yet another example of how NASA’s Technology Transfer Program within the agency’s Space Technology Mission Directorate drives innovation in commercial industry.

Keep Exploring Discover Related Topics Technology Transfer & Spinoffs

Thermal Protection Materials Branch

Thermal Protection Materials Branch

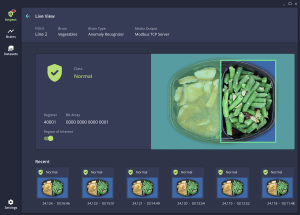

2 min read From Mars Rovers to Factory Assembly Lines NASA-funded AI technology enabling autonomous rovers and drones now keeps an eye on conveyor belts

2 min read From Mars Rovers to Factory Assembly Lines NASA-funded AI technology enabling autonomous rovers and drones now keeps an eye on conveyor belts

2 min read The View from Space Keeps Getting Better After 50 years of Landsat, discovery of new commercial and scientific uses is only accelerating

2 min read The View from Space Keeps Getting Better After 50 years of Landsat, discovery of new commercial and scientific uses is only accelerating

2 min read Controlled Propulsion for Gentle Landings A valve designed for NASA rover landings enables effective stage separations for commercial spaceflight

2 min read Controlled Propulsion for Gentle Landings A valve designed for NASA rover landings enables effective stage separations for commercial spaceflight